Mine plans are constrained by a defined geological model of the target mineral deposit. Carlson has modules to develop geologic models and configure mine plans. It is particularly suitable for modeling and planning bedded deposits like trona, coal and limestone for open and underground mines. In Carlson, we are able to create plans with varying levels of detail and precision. The plans can be high level conceptual plans good for project assessment to justify resource allocation, or detailed executable de-risked plans that include highly granular production schedules, with built-in allowances for planned and unplanned delays, production sequence, forecast production tons and grade for any given period during the life of the project.

One key aspect of mine planning, especially long-term strategic planning, is the generation of options testing alternative configurations of a mine plan to select a well-thought-out robust and efficient plan that remains flexible and responsive to changing conditions in mine and market conditions. Carlson accomplishes this through testing different layouts, production rates, equipment fleet sizes and roster adjustments.

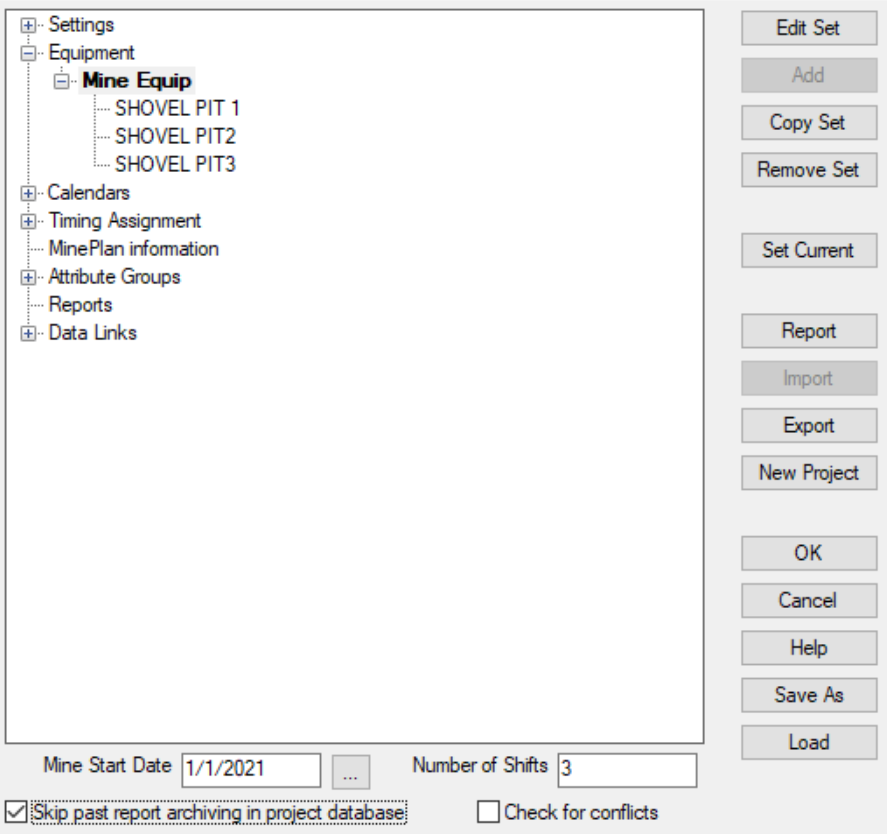

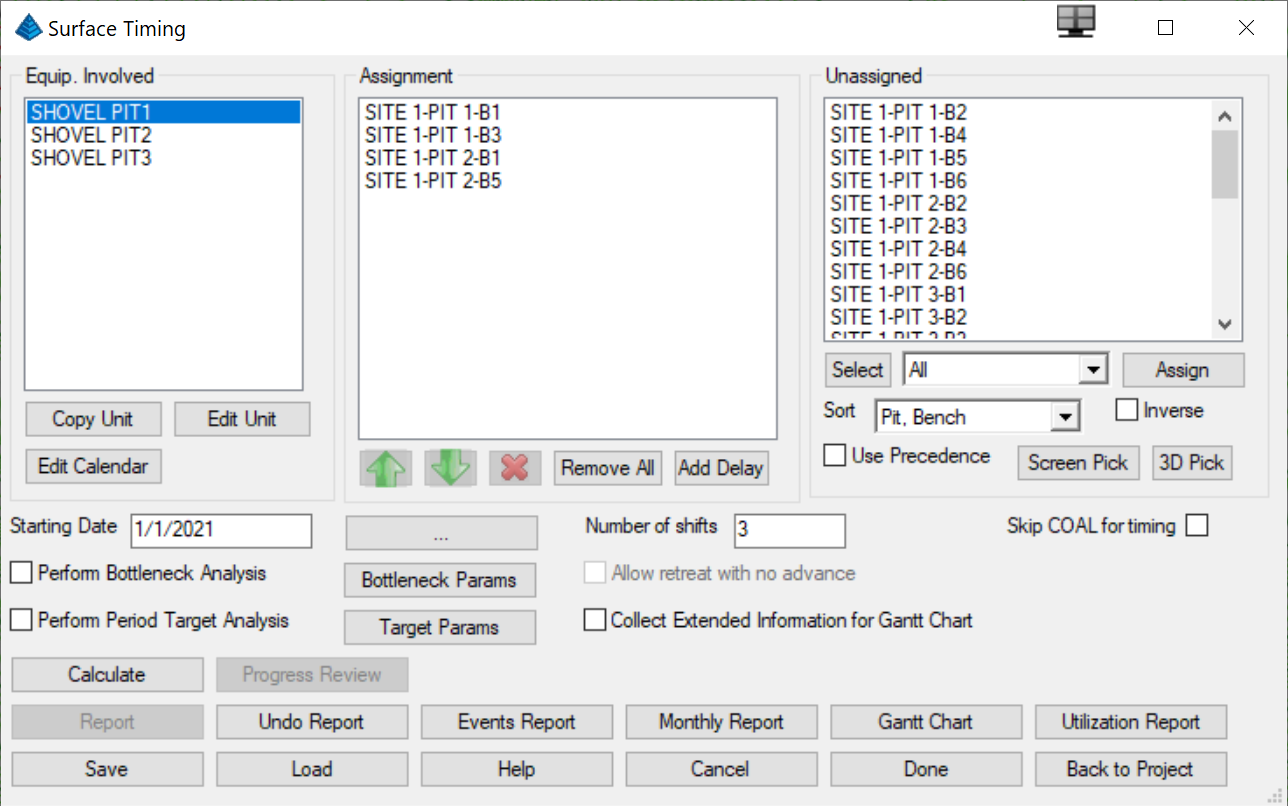

Carlson has a user friendly timing/scheduling function where equipment parameters are set and specific pieces of equipment such as shovels are assigned to particular mining blocks and calendar definitions with rules for holidays, weekends, workdays and equipment and crews are configured. This function looks similar in both the underground mine and the surface mine planning workflows. Below is a screenshot to the Carlson timing function interface.

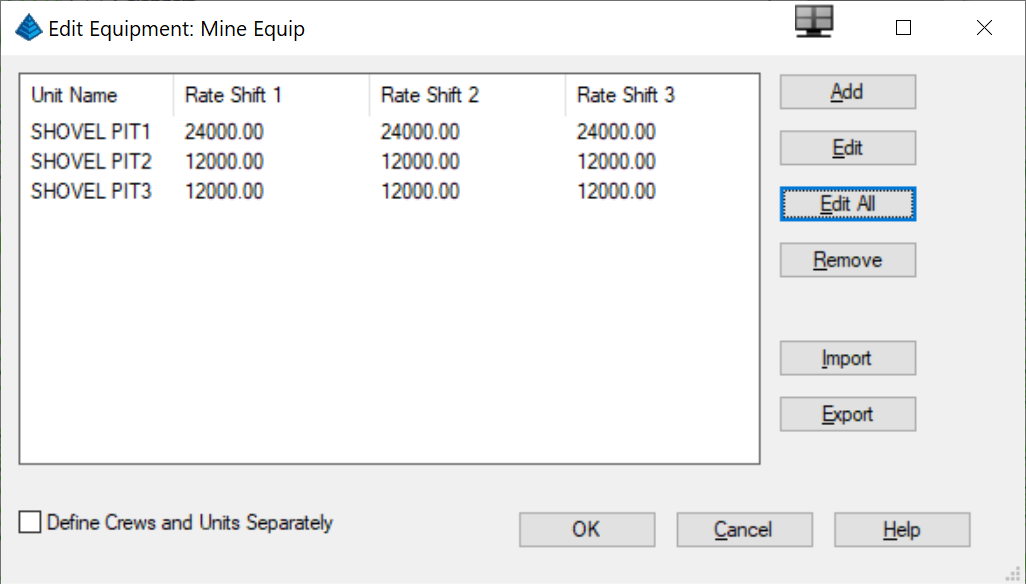

Next, we see in the screenshot the assigned rates for pieces of equipment working in different pits of a mine. There a lot more equipment parameters that can be configured for a piece of equipment. For example, availability, extraction factor, the unit of production (cubic yards, linear, tons etc.), a factor for the level of difficult to mine a particular section of the mine and many more.

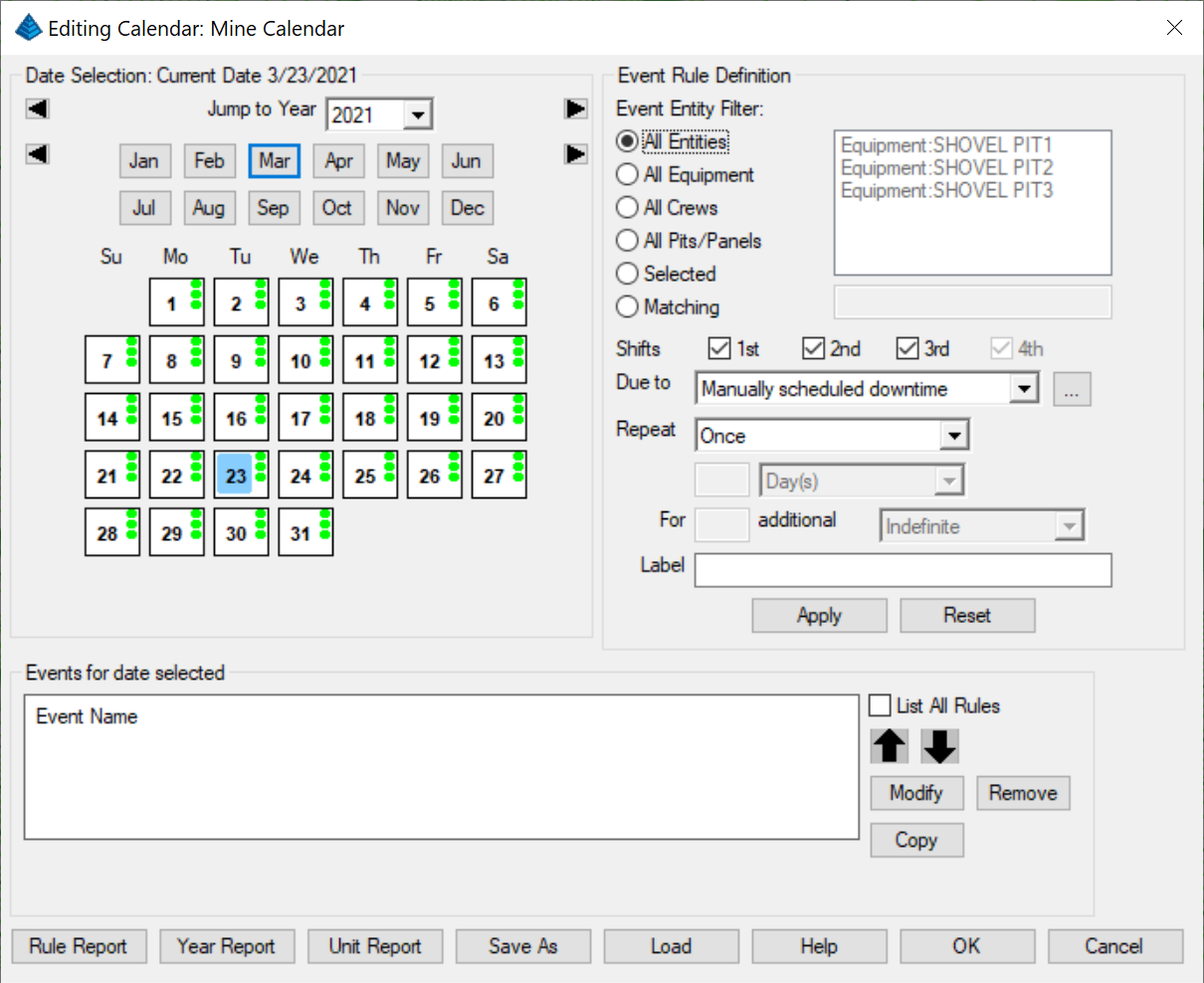

Parameters to do with working time can be configured on the interface in the screenshot below. Configuring is done on an all equipment, all crew, all mining block basis or very specifically targeted at just some entities.

Assigning equipment to different mining blocks along with options for report generation and modifications to the mine plan and other additional analysis is available also.

Below are examples of complete underground mine and surface mine sequence simulations that incorporate aspects of descriptions above.

We can also calculate total mine reserves in Carlson to assess the overall size and economic limits of the deposit. Here we get quantities and qualities(grades) of the mineral either directly from drillholes or a geologic model. This is typically a step that takes place before a detailed mine plan is developed to see mine progress defined by time period without equipment. It’s a good way to estimate the life of mine of the project.

Other mine planning and design packages I have worked with in the past include RPM Global’s XPAC and Deswik. These packages incorporate similar mining principles and concepts that Carlson does, but have different strengths and weakness that are inherent to the key drivers and needs they were designed to address. XPAC for example has great animation capabilities to simulate the mine sequence as well as an intuitive drilldown capability from the deposit level down to the smallest mining block to query the characteristics of the deposit at each level.

Deswik has great solids modeling capability and because it’s the latest to be put on the market of the three packages, it has better integration of the entire mine planning workflow that incorporates a mine specific Gantt-chart-style scheduler.

Some of the recent advances in mine planning and scheduling packages in the last decade include1:

- Linking activities using mining logic. For example, in an open pit mine, a block of ore cannot be mined before the one above it is mined.

- Applying mining rules, priorities and resource pools, to constrain capacity and mining rate based conditions encountered.

- Provide customizable reporting and customizable time-period reporting;

- Apply solver logic to optimize schedules

- Provide Gantt-chart-style visualization.

-

Advances in mine planning and scheduling packages (https://im-mining.com/2016/01/25/choosing-geological-modelling-scheduling-and-mine-planning-software/) ↩︎